ERP: Making Customers Feel Like VIPs – A. Leiser AG’s Systematic Approach

What is ERP and Why Should It Be the Cornerstone of Every Successful Dealership?

Enterprise Resource Planning (ERP) is a software system that helps organizations manage and integrate key business processes on a unified platform. It typically includes modules for functions like finance, human resources, supply chain, manufacturing, and customer relationship management (CRM). By centralizing data and automating processes, ERP systems improve efficiency, enhance decision-making, and provide a comprehensive view of a dealership’s operations.

How to Leverage it at My Dealership?

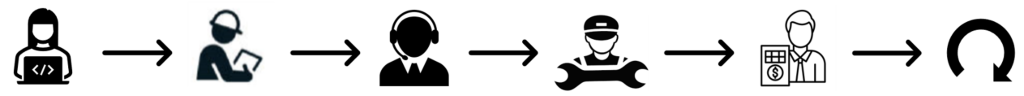

A. Leiser AG is one of the dealers using their ERP partner company for nearly all processes across the organization. All service orders, from scheduling to billing, are processed through this program. Every Bobcat machine is stored in the customer’s system as a service object, complete with its entire service history and status. Let’s take a look at how the whole process works:

The Service Lead collects information from the customer and compiles it with internal data, including historical information and real-time data from Machine IQ. This package is then given to the diagnostician, who reviews the available data and compiles a list of necessary materials. The ETL then places the order for these materials.

Based on the previously collected information, the mechanic performs the entire service process for the customer and updates the system with the necessary data (used materials, services, hours, etc.). Once the job is complete, the controller conducts a technical follow-up and releases the project for invoicing, ensuring all data is saved for the next service activity, which can be scheduled in the system.

This is a great example of how to create service opportunities and foster customer loyalty!

Already have your own ERP system? Connect it to Machine IQ and boost your experience!

The Bobcat Premium API (AEMP) in Machine IQ is a specialized interface designed to interact with the Machine IQ data platform. It provides a set of protocols and tools that enable verified developers and companies to access, manage, and utilize data generated by Bobcat machine telematics devices.

APIs require an active Machine IQ subscription to access endpoints. Refer to the following table for the data points available at each subscription level:

| Data Point | Standard | Premium |

|---|---|---|

| Location | X | X |

| Cumulative Operating Hours | X | X |

| Fuel Remaining | X | X |

| DEF Remaining | X | X |

| Engine Status | X | X |

| Diagnostic Codes | X | |

| Fuel Used | X | |

| Cumulative Idle Hours | X |

Validation is required before API access is granted:

- The customer must have an active Machine IQ account.

- The Customer Admin must be an active user of the company account.

- The first name, last name, and email address must be correct.

- All requested serial numbers must be assigned to the customer’s company account with an active subscription.

For specific and detailed information, it is best to refer to Bobcat’s official documentation:

- We follow AEMP and ISO standards. Full details can be found at developer.bobcat.com.

Interview with René Betschart, CEO

We’ve also asked René Betschart, CEO and owner of A. Leiser AG, to do a short interview about his experience with ERP so far. But first, let’s hear a few things about René himself.

How many years have you been working in the industry?

I have been working in the industry for 5 years since I took over Leiser AG at the end of 2019. Before that, I spent 23 years in various management positions in the semiconductor industry.

How long have you been with Bobcat?

We have been working with Bobcat for 28 years, since 1996.

Who are you when you’re not working?

I’m married, and we have two adult sons, aged 18 and 19. In my free time, I enjoy playing a lot of sports, including gym workouts, mountain biking, and mountaineering. I also like spending time in my garage working on vintage motorcycles and cars.

Let’s continue with your ERP system, which seems to be working flawlessly. Could you share with us its three key benefits?

First, we have all relevant data in one system, accessible at any time and from any place. This improves efficiency, as people no longer waste time searching for missing information.

Second, with the new ERP system, once a project or order is completed and the machine leaves our workshop, all invoicing data is ready in the system. This has significantly improved our invoicing process, which is very important for cash flow and liquidity.

Finally, since we have all service data available in the ERP system, we can proactively acquire customers when we notice that workshop loading is expected to be low in the coming weeks. This helps us ensure that our workshop is always fully booked.

Was it difficult for employees to adapt to the new system?

Humans are creatures of habit; whenever something new comes along, some employees find it difficult to adapt at first. To make the transition to a new system easier, proper employee training is essential.

Could you describe your experience with Machine IQ integration?

The real-time data from Machine IQ is important for scheduling service orders in advance, allowing us to prepare the right technician, materials, and priority for each task.

Where would you advise other dealers to start if they would like to follow in your footsteps?

Start by conducting a thorough benchmark or requirements analysis to find the right ERP solution, as there are plenty of options out there. Your choice should reflect your company’s size, services, and specific needs, as some ERP systems will fit better than others. Remember, this is an investment that should last 10 to 20 years, and switching later can be both expensive and a hassle. So, take the time to make the right choice!