Bobcat Hydraulic Breakers Service Parts

Bobcat HB Series Hydraulic Breakers

Hydraulic breakers are amongst the most popular attachments. They turn your compact loader or excavator into a powerful and precise demolition machine, providing enough power to break through concrete, rock, and asphalt effortlessly.

Renowned for their reliability and robustness, Bobcat HB breakers will deliver years of service. These are the reasons why more than 10 000 Bobcat Hydraulic Breakers have been sold.

Bobcat Hydraulic Breakers Maintenance

Bobcat HB breakers deliver outstanding reliability, and with proper maintenance and service can serve for a lifetime. To maintain their original performance, we recommend performing the following three actions to ensure maximum performance. For detailed instructions about service and maintenance, check the full Bobcat HB Series Hydraulic Breaker Service Manual 6904105.

1. Daily greasing and weekly inspection

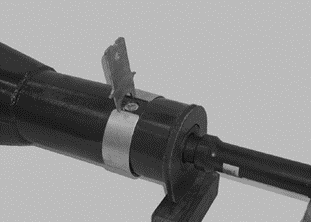

Greasing and maintenance of the tool retention system is a basic operation that should be done regularly. Thanks to the removable silver clip, it’s very easy even on-site. All you need is a Check and maintenance multitool, specific for each breaker model, and a grease gun.

It is recommended to apply Bobcat Supreme HD grease (PN 6987889) or Montabert Breakerlub (PN 86799152) to the grease fitting every 4 hours of operation or sooner if the tool looks dry.

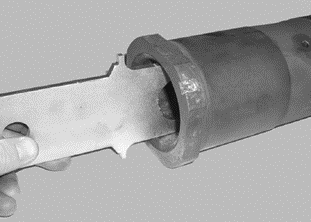

Greasing is also the perfect moment to check the tool, retaining pin, and one-piece bushing wear. The bushing keeps the piston and tool perfectly aligned. A worn bushing may result in reduced performance and eventually can damage the piston of your breakers, risking irreversibly internal damage and contaminating the entire hydraulic system of the machine. Bushings are also available separately and should be replaced if indicated by the multitool.

Inspect the tool, retaining pin, and bushing weekly.

2. 500 hours service

Bobcat HB breakers are fully serviceable. You can perform a complete overhaul in less than 3 hours – a fraction of the time needed for rebuilding some other breakers.

The urethane bushing must be replaced after every 500 hours of service. It is recommended to rebuild the breaker every 500 hours or once a year using a Rebuild Kit.

Rebuild kit part numbers by breaker model, and other parts required for service and maintenance are shown in a table below.

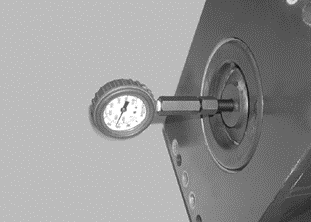

3. Annual nitrogen chamber charge pressure checking

Correct nitrogen charge pressure is an important factor in the service life of the breaker. When the charge is too low, the breaker will cycle faster than intended reducing the life of the diaphragm. A low charge also causes the breaker to not hit as hard as designed, reducing performance. When the charge is too high, the breaker will cycle slower than intended and build excessive heat, affecting the performance and service life of the breaker and carrier.

A service interval of 12 months has been established for checking the nitrogen charge.

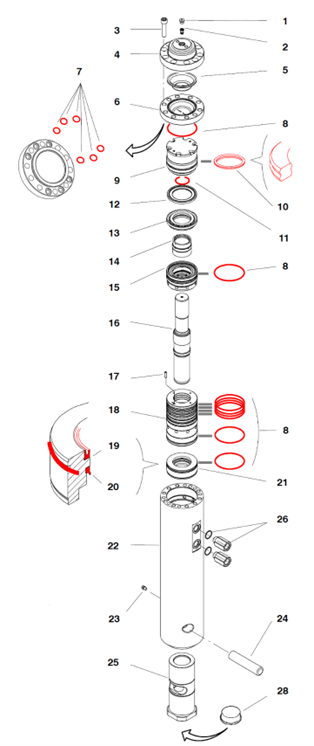

- 1 – Plug

- 2 – Valve

- 3 – Screw

- 4 – Upper flange

- 5 – Diaphragm

- 6 – Lower flange

- 7 – Seal

- 8 – O-ring

- 9 – Piston cover

- 10 – Seal

- 11 – Seal

- 12 – Valve

- 13 – Distributor cover

- 14 – Distributor

- 15 – Distribution box

- 16 – Strike piston

- 17 – Pin

- 18 – Cylinder

- 19 – Seal

- 20 – Scraper seal

- 21 – Seals casing

- 22 – Body

- 23 – Oiler

- 24 – Retaining pin

- 25 – Bushing

- 26 – Adaptor

- 27 – Threaded plug

- 28 – Plastic plug

- Seal kit – ref. 7, 8, 10, 11, 19 & 20

- Rebuild kit – 5, 7, 8, 10, 11, 12, 19 & 20

NOTE: Above is an example of HB680 breaker for illustration purposes and can differ from other models.

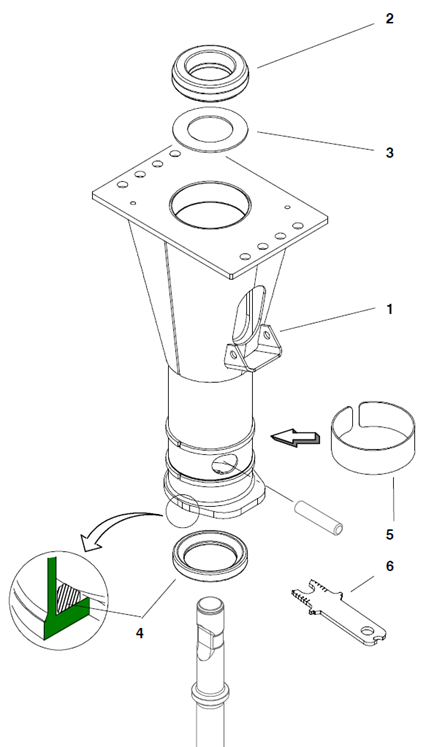

- 1 – Housing

- 2 – Upper dampener

- 3 – Bearing plate

- 4 – Lower dampener

- 5 – Retainer clamp

- 6 – Check and maintenance multitool

NOTE: This image is an example of HB680 breaker for illustration purposes and can differ from other models.

List of common Bobcat HB breakers kits and parts