Ring Brushes

Choose the Right Bobcat Bristle

Bobcat offers multiple ring brushes for more versatility when meeting your sweeping needs. Ring brushes are available in two materials: polypropylene or steel wire with two main styles: convoluted (Zig-Zag) and flat.

- The polypropylene, steel wire, and poly/wire combo bristle options are designed to suit various sweeping conditions and requirements.

- Convoluted rings have a wavy shape and when aligned correctly, do not need a spacer. Flat rings are typically mounted with a spacer between each ring.

For more information about ring brushes and part numbers, please refer to chapter RING BRUSHES, GUTTER, BRUSHES & WHISKER BROOM BRISTLES in the latest version of our Big Red Book.

Standard Applications

For standard applications, we refer to situations where the best sweeping action is required, such as leaf removal, cleaning loose road debris, and clearing new snow. These are typically applications where the cleaned material doesn’t need to be broken up and/or when operating on sensitive surfaces, like coated floors, that must not be harmed. Polypropylene ring brushes are the best choice for these scenarios.

Polypropylene Brush / Polypropylene Inner Ring

Designed for effective debris removal under normal sweeping conditions (asphalt debris, clay, gravel, light snow, sand, and other road debris)

- Polypropylene brushes, with a thickness of 2.5-4 mm, enhance ring longevity

- Non-corrosive material suitable for all weather conditions

- 100% recyclable

Polypropylene Brush / Steel Inner Ring

Designed for sweeping asphalt, clay, gravel, light snow, sand, and other road debris

- Extremely resilient inner steel ring

- The inner ring features taps punched through the overlapping steel band for even more stability

- Polypropylene brushes, with a thickness of 2.5 mm, enhance ring longevity

Heavy-duty Applications

Heavy-duty applications necessitate breaking up the cleaned material before it can be swept up. This includes tasks such as removing packed mud or snow from roads and cleaning ice or pieces of foreign materials adhering to the surface. In such applications, an aggressive cutting action, delivered by steel wire bristles, is required. It’s important to note that heavy-duty application rings are not recommended for sensitive surfaces, as steel wires could potentially cause damage to the floor.

Steel Brush / Steel Inner Ring

Designed for heavy-duty applications and breaking up packed materials such as asphalt, gravel, packed clay, mud, or snow, steel wire rings do not possess the same sweeping capability as polypropylene rings. Therefore, it is not recommended to use wire rings alone. Typically, they are combined with polypropylene rings on a single attachment. To achieve the best of both worlds, combine one wire ring with one poly ring and so on. This system is compatible with both flat and convoluted rings.

- Extremely resilient inner steel ring

- Steel brush material tied with steel wire

- Steel brush material is also glued to the inside the inner ring as an extra precaution

- Taps are punched through the inner ring for more stability

Poly-steel Brush / Steel Inner Ring

Get the best of both worlds with poly bristles and wire bristles on one wafer. This ring combines both sweeping and cutting capabilities and simplifies installation.

- Designed for medium to heavy-duty applications

- Extremely resilient inner steel ring

- Combines the flicking action of poly bristles with the aggression of wire bristles

- Ideal for all sweeping conditions

Flat or Convoluted (Zig-Zag) Rings

Ring brushes are available in two main styles: convoluted (Zig-Zag) and flat.

Convoluted rings have a wavy pattern, and when aligned correctly, they do not require a spacer. This solution simplifies installation and eliminates the need for spacers, although more care is needed during fitting. The convoluted design features high and low spots around the ring that must be aligned correctly. Each ring should be rotated a quarter turn on the rack.

Flat rings are typically mounted with a spacer between each ring, following the pattern of ring, spacer, ring, spacer, and so on. Since they are flat, they do not need to be placed on the rack in any specific order, making installation somewhat easier. Flat rings also enable experimentation with assembled brush density – by omitting spacers, it is possible to fit more rings on the spindle for a denser brush.

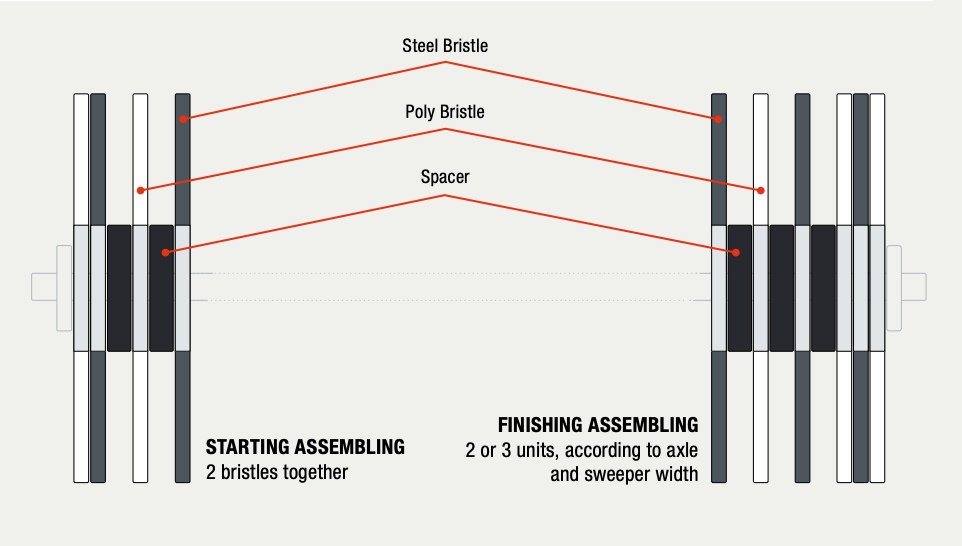

Combining Materials

The easiest way to get the best of both worlds is by using Poly-steel combo ring brushes. However, similar results can be achieved by combining both types on one attachment. This combination also allows for experimentation with various ratios of poly and wire rings to achieve ideal results. Below is an example of a 50%/50% configuration that combines poly and wire convoluted rings with flat rings on the edges.

For more information about ring brushes and part numbers, refer to the chapter RING BRUSHES, GUTTER, BRUSHES, & WHISKER BROOM BRISTLES in the latest version of our Big Red Book.