Steel Tracks for Excavators

Why steel tracks?

Sometimes it’s needed to modify a machine for a specific application. Do you need something a bit more heavy-duty than typically used rubber tracks? For jobs in quarries, forestry, demolition or any application where rubber tracks damage is common, steel tracks can be the solution.

Selected Bobcat excavators can be used with steel or hybrid segmented tracks. Depending on the model it can be as simple as changing the original rubber tracks to steel ones without any modification, or a more complex procedure requiring the replacement of undercarriage components. Bobcat offers both conversion kits, containing rollers, idlers and individual steel tracks. In specific cases it may be required to purchase additional parts even when buying a conversion kit. Before ordering steel tracks or kits, carefully consult the possible need for additional components in our Parts Catalog.

Download overview of Steel Tracks, Kits and their compatibility to models:

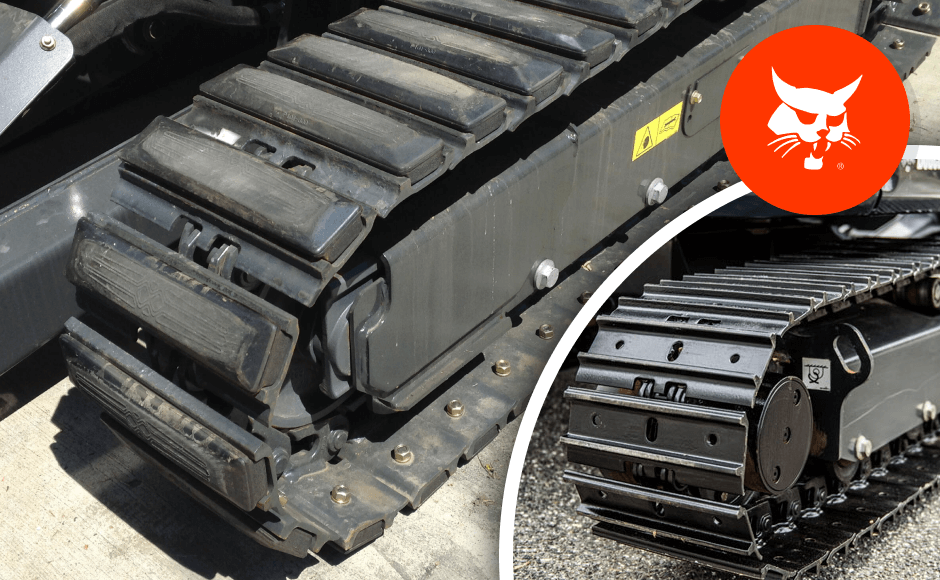

Steel tracks

Steel tracks have been used on large excavators or dozers for decades but are not commonly used on compact equipment. It doesn’t mean that there is no need for them. Steel has a much longer life than rubber tracks without sacrificing flotation. Steel tracks have also better traction, which is a real benefit to machines working in dirt, snow or ice.

The conversion from rubber tracks is not cheap, but under certain circumstances it can be a great investment. Steel tracks will likely last a machine’s lifetime and can be the last set of tracks customers will ever need. No more costs related to changing rubber tracks and downtime caused by failures. In the right situation, an investment steel tracks will quickly return.

Steel tracks aren’t right for everyone. They are hard on ground, so they should not be used in sensitive applications. Also, operators need to avoid running steel tracks on hard surfaces, like asphalt and concrete. That’s where a classic rubber or segmented hybrid tracks work much better.

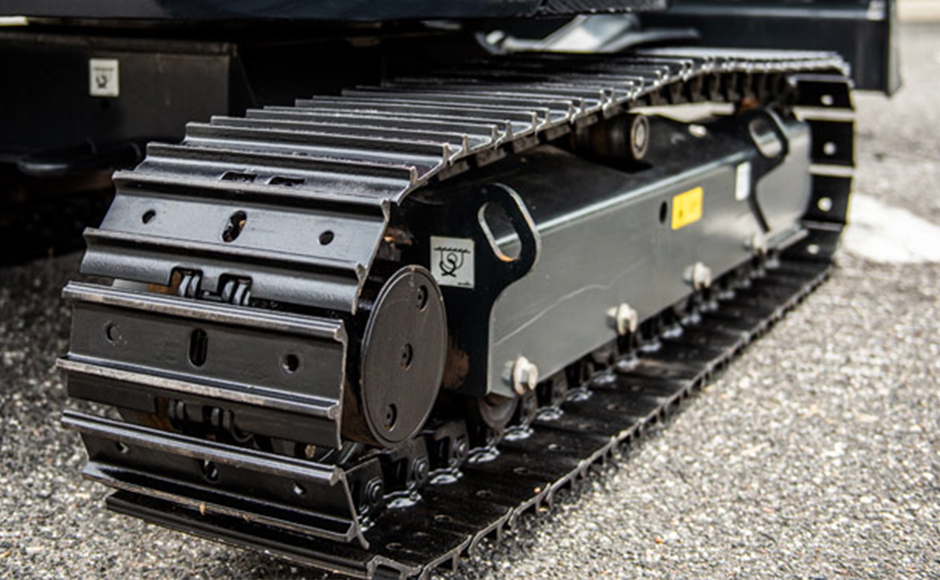

Segmented tracks

Selected Bobcat models can be alongside steel tracks fitted with tracks with segmented construction. Replaceable rubber pads enable quick and convenient repair and ensure a more comfortable ride and less ground damage.

Hybrid segmented tracks combine the durability of steel tracks with the ride comfort and versatility of rubber tracks. Segmented tracks are a combination of heavy-duty steel chains with bolt-on hybrid pads. Segmented tracks are the best of both worlds — a replacement for a rubber track that can be repaired, when damaged, while still retaining the versatility to perform the job of a rubber track.

Segmented tracks are more durable than rubber tracks. Their design doesn’t require the rubber to flex like a rubber track. A harder rubber can be used, which will hold up better on hard surfaces and in applications like demolition, where sharp surfaces can destroy rubber tracks. With this system the pads can be replaced without having to change the whole track. Like steel tracks, segmented tracks can cause more damage to surfaces.